A modular workbench system allows the tailoring of a workstation to the exact needs of a customer. These systems have many configurable parts such as drawers, cabinets, pegboards, shelves, and lockers. Workers doing tasks that need many parts and tools benefit from having all materials close at hand. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

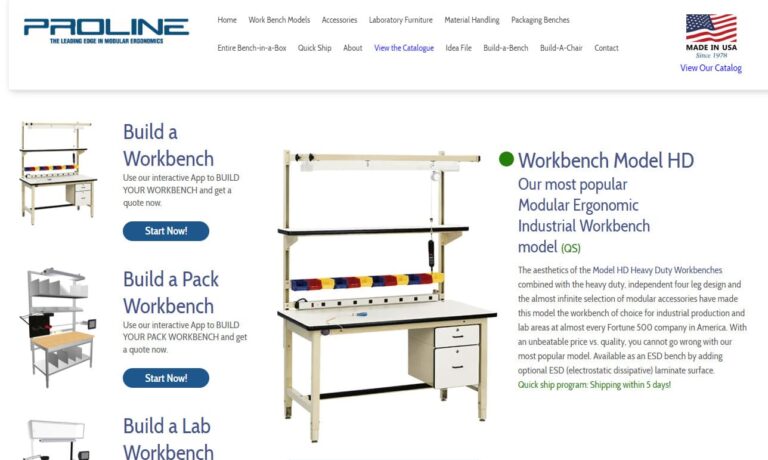

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More Modular Workbench Manufacturers

Modular Workbench Systems: The Ultimate Guide for Industrial and Commercial Applications

Modular workbench systems combine a durable work surface with a wide range of storage solutions that can be tailored to meet any organization's workflow, productivity, and safety needs. Whether you operate a manufacturing facility, electronics lab, automotive shop, or office, modular workbenches offer unmatched flexibility for optimizing workspace layout. By leveraging multiple configurations, businesses can maximize efficiency, improve ergonomics, and support evolving operational requirements.

Key Considerations When Choosing a Modular Workbench

Investing in modular workbenches is a strategic decision that can directly impact productivity, safety, and employee satisfaction. Below, we explore the most important factors to evaluate when selecting the ideal modular workbench system for your facility or workspace.

1. Modular Workbench Shape, Size, and Configuration

One essential advantage of using a modular workbench is the capability to choose the precise shape and size that best fits your specific environment. Popular configurations include:

- Linear (row) layouts ideal for assembly lines, packing stations, and production facilities.

- U-shaped and L-shaped workbenches for enhanced collaboration and efficient movement within work cells.

- Curved or corner workstations that optimize space utilization while enabling group communication.

- Mobile modular workbenches equipped with casters for flexible, reconfigurable work environments.

These adaptable structures allow organizations to maintain open floor space, support changing workflows, and quickly add or remove workspace as business needs shift. Modular workbench legs ensure stability in high-traffic or heavy-duty environments, while drawers, filing cabinets, tool chests, and elongated benchtops can be integrated with minimal effort. The modular design means assembly and disassembly are quick and do not require professional installation, reducing setup costs and downtime.

Are you looking for the best modular workbench layout for your industry?

Explore industry-specific modular workbench configurations to discover the optimal shapes, sizes, and accessories for your unique requirements.

2. Modular Workbench Ergonomics and Workplace Safety

Ergonomics is a critical factor in modular workbench design, directly influencing worker comfort, safety, and productivity. Poor ergonomics can result in repetitive strain injuries, musculoskeletal disorders, and lost workdays due to workplace harm. Modular workbenches with adjustable height features, tilt surfaces, and customizable storage ensure employees can perform tasks in optimal postures, reducing fatigue and injury risk.

For example, workbench designs with hand cranks or electric lifts enable users to elevate or lower the desk height to match their physical stature or specific job duties. This is especially important in environments with multiple shifts or diverse staff. Ergonomic accessories such as anti-fatigue mats, footrests, and monitor arms further enhance comfort and reduce workplace injuries. Additionally, modular workbench systems can be fitted with specialized storage for frequently used tools and supplies, keeping everything within easy reach.

Curious about improving employee health and productivity?

Learn more about ergonomic modular workstations and how adjustable features can transform your workspace.

3. Modular Workbench Surfaces and Materials

The choice of workbench surface material is crucial and should be matched to your specific application. Common options include:

- Plastic laminate surfaces: Ideal for office settings, lightweight assembly, and environments where easy cleaning and hygiene are essential. These non-porous surfaces resist stains and can handle moderate weight loads.

- Solid wood butcher block: Provides a sturdy, resilient work surface for woodworking, assembly, and light manufacturing. Wood surfaces are gentle on tools and parts and offer a classic appearance.

- Stainless steel: The gold standard for laboratories, cleanrooms, food processing, pharmaceutical, and high-moisture environments. These surfaces are resistant to heat, corrosion, and harsh chemicals.

- ESD (Electrostatic Discharge) surfaces: Critical for electronics manufacturing, repair, and testing, these specialized surfaces protect sensitive components from static damage.

For setups exposed to direct sunlight, opt for anti-glare surfaces to minimize eye strain. In wet or humid conditions, stainless steel is recommended to prevent rust and microbial growth. Modular workbench manufacturers typically offer a variety of surface options to meet any industry need.

Not sure what material is best for your modular workbench?

Check our workbench material comparison table for detailed pros and cons tailored to popular use cases.

4. Modular Workbench Ease of Use and Workflow Optimization

Modular workbench systems streamline operations by minimizing unnecessary movements and improving organization. Features such as integrated gravity-fed conveyors, adjustable shelving, and dedicated tool storage ensure that materials flow efficiently through workstations. For example, point-of-use conveyors automatically deliver parts or packages to workers, reducing walking and manual handling.

This first-in, first-out (FIFO) setup is ideal for repetitive processes and high-throughput environments such as order fulfillment, product assembly, packaging, and quality control. The result is a workspace that enables faster task completion, reduces error rates, and increases profitability. Additionally, modular systems can be reconfigured as operations scale up or shift focus, providing long-term value and adaptability.

Key user-focused advantages of modular workbench solutions include:

- Purpose-Built Layouts: Modular workbench cabinets and accessories keep tools, components, and documentation organized, safe, and easily accessible. Each element functions as a standalone unit or as part of a comprehensive system.

- Advanced Customization: Workbenches can be customized with locking drawers, overhead lighting, power strips, pegboards, bin rails, and computer mounts, tailoring each station to the exact task or operator.

- Space Optimization: Vertical shelving and under-bench storage maximize every square foot, accommodating supplies of various sizes and improving inventory management.

- Ergonomic Workspace: Height-adjustable benches and modular accessories ensure a fit for every worker or task, reducing strain and boosting morale.

- Boosted Efficiency: Having tools and materials within arm’s reach reduces wasted motion, allowing employees to focus on value-added activities.

- Flexible Inventory Management: Modular accessories and components can be shared and relocated as needs change throughout the facility.

- Empowered Workforce: Modularity lets staff personalize their workspace, promoting ownership and higher job satisfaction.

How can modular workbenches improve your facility’s workflow?

Contact us for a free workflow assessment or explore our customer case studies to see real-world productivity gains.

Applications of Modular Workbenches Across Industries

Modular workbenches are utilized in a wide range of industries, each with unique requirements and operational challenges. Below are some of the most common applications and the benefits modular solutions bring to each environment:

Manufacturing and Assembly

Manufacturers rely on modular workbench systems for assembly lines, quality inspection, kitting, and subassembly processes. Heavy-duty modular benches with integrated tool storage and power options help reduce downtime and speed up production. ESD-safe surfaces and adjustable heights are often required for electronics and precision manufacturing.

Automotive and Mechanical Repair

Automotive repair shops and mechanical workshops benefit from modular workbenches with built-in tool drawers, oil-resistant surfaces, and heavy-load capacities. Mobile workbenches can be rolled to different service bays, while wall-mounted pegboards and parts bins keep fasteners and components organized and accessible.

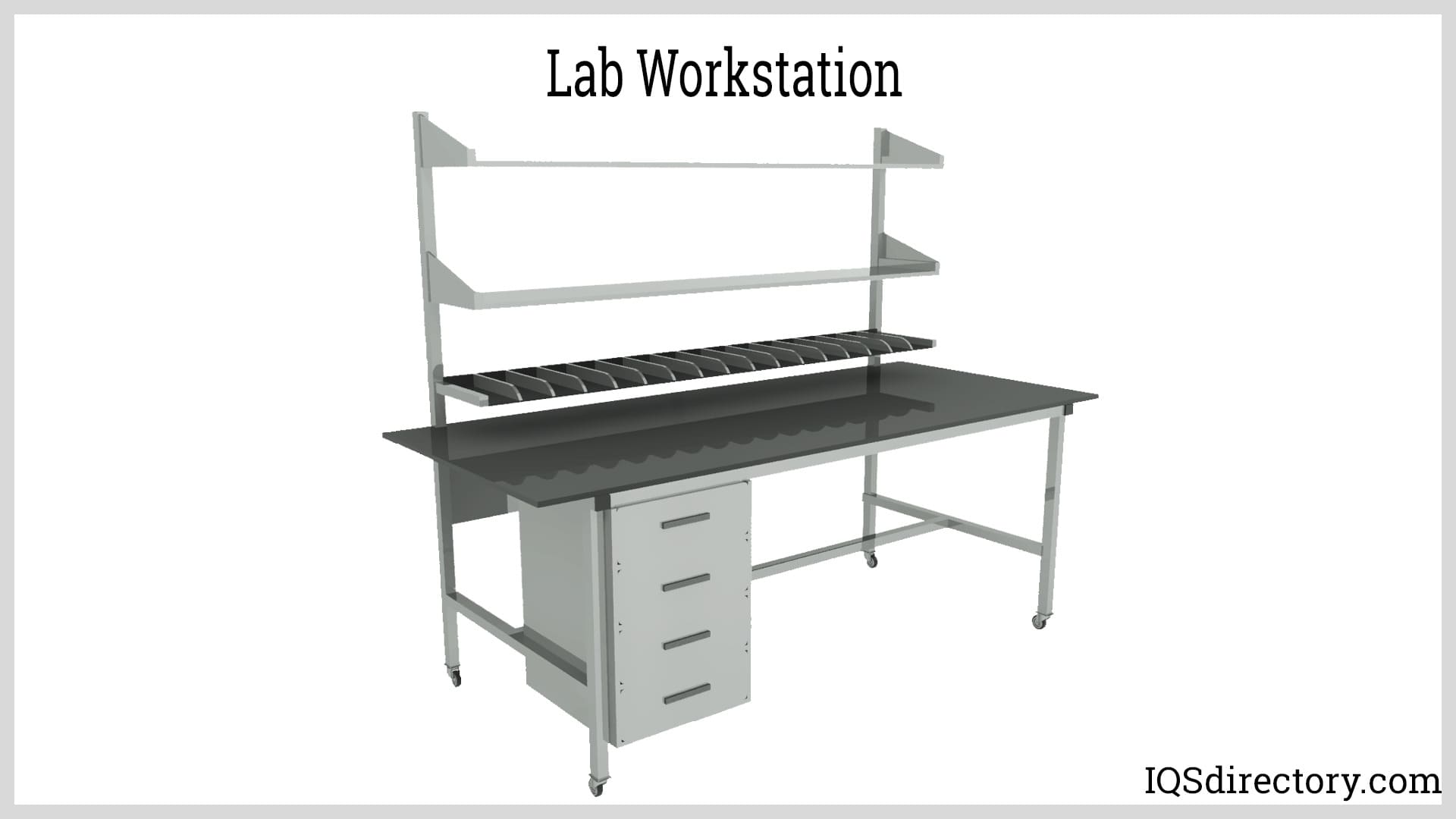

Laboratories and Cleanrooms

Labs and cleanrooms require modular benches with stainless steel or chemical-resistant surfaces, integrated sinks, and anti-microbial coatings. These environments demand strict hygiene and easy disinfection, making modularity essential for adapting to new research tasks or protocols.

Electronics and Technology

Electronics assembly, repair, and testing facilities use modular ESD workbenches with grounding points, shelving for oscilloscopes and meters, and integrated lighting. Flexible configurations allow for rapid retooling as product lines evolve.

Packing, Shipping, and Logistics

Fulfillment centers and warehouses use modular packing stations with gravity-fed conveyors, label printers, and vertical storage, ensuring fast and accurate order processing. Modular workbench systems can be scaled up or down as order volumes fluctuate.

Educational, Office, and Creative Spaces

Schools, universities, and makerspaces value modular workbenches for their versatility in supporting STEM labs, art studios, and collaborative projects. Offices use modular benches as technical desks and project tables, while mobile units allow for rapid reconfiguration during events or space redesigns.

Wondering if modular workbenches are right for your industry?

Browse our industry solutions or request a custom quote to match your specific use case.

Major Benefits of Modular Workbenches

- Flexibility and Scalability: Easily reconfigure workspaces as your business grows, adapts to new products, or changes processes.

- Enhanced Productivity: Thoughtfully organized workstations reduce wasted time and motion, supporting lean manufacturing principles.

- Improved Employee Morale: Personalized, ergonomic stations contribute to employee satisfaction and retention.

- Cost Savings: Minimize installation, maintenance, and reconfiguration costs versus fixed or custom-built furniture.

- Space Optimization: Maximize use of available square footage with vertical and under-bench storage options.

- Future-Proof Investment: Modular systems support evolving technologies and workflows, delivering long-term value.

Ready to upgrade your facility with modular workbenches?

Get started by comparing top modular workbench suppliers and requesting quotes tailored to your needs.

Modular Workbench Surface Material Comparison

| Material | Best For | Benefits | Considerations |

|---|---|---|---|

| Plastic Laminate | Offices, light assembly, clean environments | Easy to clean, affordable, lightweight | Not suitable for heavy-duty or high-heat tasks |

| Butcher Block | Woodworking, light manufacturing | Durable, gentle on tools, attractive appearance | Requires periodic sealing, can be damaged by chemicals |

| Stainless Steel | Labs, food processing, high-moisture | Corrosion/heat resistant, hygienic, easy to sanitize | Higher cost, can be noisy |

| ESD Laminate | Electronics, tech labs | Protects sensitive components, anti-static | Requires grounding, higher upfront cost |

How to Choose the Right Modular Workbench Supplier

When purchasing modular workbenches, selecting the right supplier is essential for ensuring product quality, timely delivery, and post-purchase support. Here’s how to make an informed decision:

- Compare Multiple Suppliers: Evaluate at least four modular workbench manufacturers using our comprehensive supplier directory. Review each supplier’s business profile, areas of expertise, and customer reviews.

- Assess Capabilities: Check for manufacturers who offer custom configurations, rapid lead times, and a wide range of modular accessories.

- Request Product Samples: Ask for material swatches, CAD drawings, or demo units to ensure compatibility with your operational needs.

- Use Our Website Previewer: Quickly browse and compare supplier websites to see detailed product specs, case studies, and downloadable resources.

- Streamline Your RFQ Process: Use our simple Request-for-Quote form to contact multiple modular workbench companies at once, saving time and getting competitive pricing.

What should you ask a modular workbench supplier?

- What industries do you specialize in supplying?

- Can you provide references or case studies in my sector?

- What is your lead time for custom configurations?

- Do you offer onsite installation and post-purchase support?

- What warranty and maintenance services do you provide?

To ensure a successful purchase and long-term satisfaction, partner only with suppliers who meet your technical, logistical, and budgetary requirements. Our supplier comparison tool and expert resources make it easy to find the best fit for your modular workbench needs.

Frequently Asked Questions About Modular Workbenches

What is a modular workbench?

A modular workbench is a customizable workstation made up of individual components—such as work surfaces, storage units, and accessories—that can be arranged and reconfigured to suit changing tasks, workflows, and environments. These systems offer greater flexibility than traditional fixed workbenches and are widely used in manufacturing, labs, offices, and more.

How do I choose the right modular workbench for my application?

Consider your industry’s unique needs, the types of tasks performed, available space, required load capacity, and any special environmental factors (such as ESD safety or hygiene). Consult with suppliers who offer modular systems and be sure to request a site assessment if possible.

Are modular workbenches easy to assemble and reconfigure?

Yes, most modular workbenches are designed for tool-free or simple assembly, allowing for quick reconfiguration without professional installation. This makes them ideal for evolving workspaces and businesses experiencing growth or change.

Can modular workbenches support heavy equipment?

Many modular workbench systems are engineered for high load capacities, with reinforced steel frames, heavy-duty legs, and impact-resistant surfaces. Always verify the manufacturer’s specifications to ensure they meet your equipment requirements.

How can modular workstations improve workplace safety?

By enabling ergonomic adjustments, organized storage, and clear workflow layouts, modular workbenches reduce the risk of repetitive strain injuries, trips, and other workplace hazards. Features like anti-fatigue mats and ESD protection further enhance safety.

Where can I find modular workbench reviews and case studies?

Visit our case studies section or check supplier profile pages for real-world examples and customer testimonials.

Customer Success Stories: Modular Workbench Solutions in Action

Discover how organizations like yours have transformed their operations with modular workbench systems:

- Electronics Manufacturer: Reduced assembly time by 20% after implementing ESD-safe modular benches with integrated power supplies and part bins.

- Automotive Shop: Increased technician efficiency by introducing mobile modular workbenches, allowing staff to bring tools directly to each vehicle bay.

- Pharma Lab: Improved compliance and safety with stainless steel modular benches featuring easy-to-clean surfaces and lockable storage.

- E-commerce Fulfillment Center: Boosted order accuracy and packing speed using modular conveyor-integrated workstations and vertical shelving systems.

Get Started with Modular Workbench Systems Today

Modular workbenches offer unparalleled adaptability, efficiency, and ergonomic benefits for organizations of all sizes and industries. By carefully evaluating your needs, consulting with expert suppliers, and choosing the right configurations and materials, you can create a workspace that supports productivity today—and adapts to the demands of tomorrow.

Ready to take the next step? Explore our supplier directory, request a quote, or contact our modular workbench experts for personalized advice on optimizing your workspace.

55 Gallon Drums

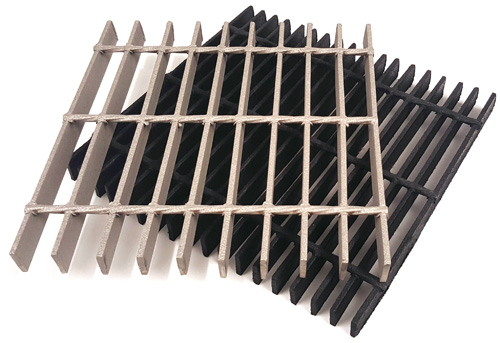

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services