Work benches are indispensable tools in various industries and settings, providing a dedicated space for tasks that require stability, organization, and accessibility. Whether you’re an electronics enthusiast, woodworker, or scientist, having a reliable work bench can greatly enhance your productivity and efficiency. These versatile workstations offer a range of components designed to meet different needs and applications. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More Work Bench Manufacturers

Components of Workbenches

A workbench is composed of several critical elements that enhance both its functionality and practicality, making it an essential piece of equipment in workshops, laboratories, garages, and industrial facilities. The work surface, often crafted from durable materials such as hardwood, stainless steel, heavy-duty laminate, or composite resin, must be flat, tough, and resistant to scratches, chemicals, and impact. This ensures a reliable and long-lasting workspace for various tasks, whether it’s woodworking, electronics assembly, or metal fabrication.

The frame and legs form the backbone of the workbench, delivering structural support and stability. High-quality industrial workbenches typically feature frames made from powder-coated steel or reinforced aluminum for maximum strength and load-bearing capacity. Adjustable height mechanisms—manual or electric—are increasingly popular, helping users achieve an ergonomic workspace tailored to their needs. For environments that require reconfiguration or flexibility, features such as locking casters or wheels allow for easy mobility.

Effective storage solutions are crucial for organization and efficiency. Integrated drawers, shelves, cabinets, and overhead racks help keep tools, materials, and accessories within arm’s reach, reducing downtime and keeping the work area tidy. Pegboards, bin rails, and modular storage systems further enhance accessibility, supporting lean manufacturing and 5S principles.

Additional components, including heavy-duty vises and clamps, provide secure workholding for cutting, sanding, soldering, or assembly. Integrated lighting fixtures—such as LED task lights—improve visibility and reduce eye strain, while built-in power outlets and USB charging ports support the use of electric hand tools, soldering irons, and diagnostic devices. Some advanced industrial workbenches incorporate ESD (electrostatic discharge) protection, fume extraction systems, or specialized mats for sensitive applications.

When designing a workbench for your workshop or facility, it’s important to consider how these components contribute to productivity, safety, and comfort. Each feature should match the specific demands of your application, whether you require a laboratory workbench with chemical resistance or a modular workbench for assembly lines.

Assembling Workbenches

Workbenches are engineered to meet the rigorous demands of various industries and specialized tasks. For electronics assembly and repair, modern workbenches boast anti-static (ESD-safe) surfaces, grounded wrist strap connectors, integrated power strips, and cable management trays for a safe and organized environment. These benches often include magnification lamps and precision storage bins to enhance productivity and protect sensitive components.

In woodworking, robust workbenches are outfitted with heavy-duty vises, bench dogs, and sacrificial tops for detailed shaping, carving, or joinery. Storage for hand tools, clamps, and adhesives is usually incorporated, while dust collection ports maintain a clean workspace. Garage workbenches for automotive and DIY applications often feature steel tops, integrated tool chests, pegboards, and hooks for organizing wrenches, sockets, and power tools. Some even have hydraulic lift sections for working on engines or transmissions.

For laboratory use, benches are constructed from chemical-resistant epoxy resin, phenolic, or stainless steel, and may include sink basins, reagent racks, fume hoods, and lockable storage for hazardous materials. Anti-vibration pads support delicate weighing or analytical equipment. Each workbench is meticulously designed to address the unique safety, functionality, and durability needs of its intended use, ensuring compliance with industry standards and best practices.

Curious about which workbench suits your industry or job function? Explore our guides on:

- How to choose an adjustable workbench for ergonomic comfort

- Benefits of modular workbenches for flexible workspace design

- Laboratory workbench configurations for research and testing

Variations of Workbenches

Electronics Workbenches

Specialized electronics workbenches are engineered to support intricate tasks such as PCB assembly, soldering, device testing, and electrical troubleshooting. Key features include:

- ESD-safe (anti-static) surfaces to prevent static discharge that could damage sensitive microchips and circuit boards.

- Integrated power supplies—including AC/DC outputs, USB, and surge-protected outlets—to power soldering irons, oscilloscopes, and meters.

- Cable management trays and wire ducts to keep cords organized and prevent tripping hazards.

- LED task lighting for detailed work and reduced eye fatigue.

- Adjustable shelves, modular drawer units, and parts bins for secure storage of components and tools.

Electronics workbenches are vital for electronics manufacturing, prototyping, repair shops, and educational labs. Looking to upgrade your electronics workstation? Compare ESD workbench models and pricing from top manufacturers in our directory.

Woodworking Workbenches

Designed for carpenters, woodworkers, and hobbyists, woodworking workbenches optimize precision and stability. Hallmark features include:

- Thick hardwood tops—often maple or beech—that absorb vibration and resist dents.

- Heavy-duty face and tail vises for holding lumber during planing, sawing, or chiseling.

- Strategically placed dog holes for flexible clamping and workpiece positioning.

- Integrated tool wells, shelves, and under-bench cabinets for tool organization.

- Optional bench-mounted jigs, router tables, or dust collection attachments.

These benches are the backbone of woodworking shops, furniture making, instrument crafting, and restoration projects. Need advice on selecting a woodworking bench for your shop? Discover best practices and top-rated brands in our buyer’s guide.

Garage Workbenches

Garage workbenches are indispensable for automotive repair, home improvement, and DIY enthusiasts. Their rugged construction and versatile design make them suitable for heavy-duty work:

- Durable steel or composite work surfaces withstand impacts, oil, grease, and solvents.

- Integrated tool cabinets, pegboards, and magnetic tool strips keep wrenches, pliers, and sockets organized.

- Optional built-in lighting, power strips, and USB charging stations for convenience.

- Some models feature hydraulic lifts or adjustable-height tops for working on engines or large components.

Whether you’re outfitting a commercial auto shop or personal garage, garage workbenches streamline workflow and maximize storage. Want to compare garage bench setups? Use our interactive comparison tool to evaluate features, sizes, and price points.

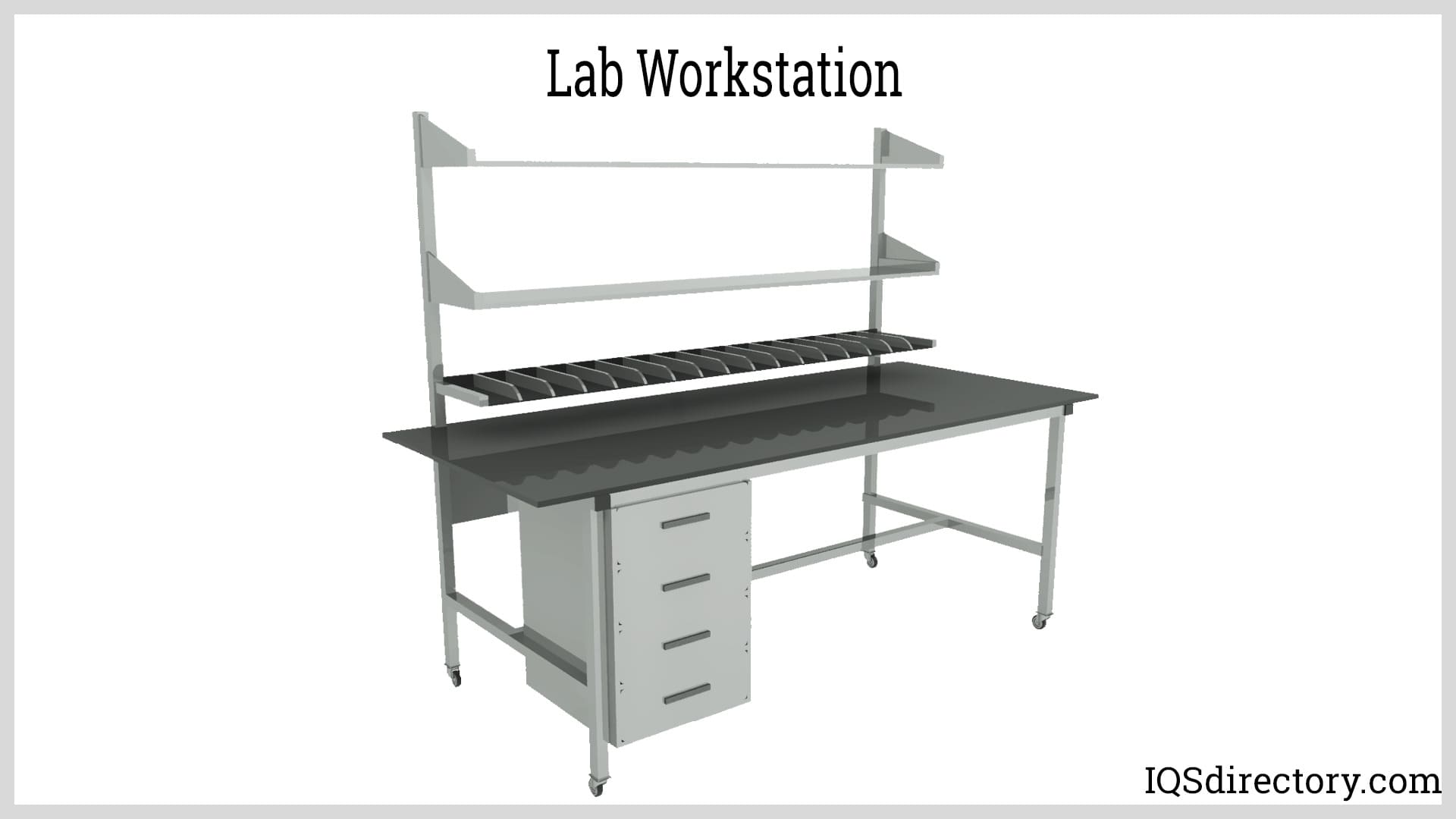

Laboratory Workbenches

Laboratory workbenches must meet strict requirements for safety, hygiene, and chemical resistance. Common features include:

- Epoxy resin, phenolic resin, or stainless steel surfaces that resist acids, solvents, and heat.

- Integrated fume hoods or ventilation systems to protect users from harmful vapors and airborne contaminants.

- Lockable storage for hazardous chemicals, glassware, and sensitive equipment.

- Height-adjustable frames to accommodate various users and experiment setups.

- Optional anti-vibration surfaces, reagent racks, and sink modules for specialized applications.

Laboratory workbenches play a critical role in research, pharmaceuticals, clinical diagnostics, and educational settings. Looking for lab bench solutions for your facility? Consult our lab furniture experts for tailored recommendations.

Each workbench type provides features and functionality tailored to its specific application, ensuring professionals and hobbyists alike can perform their tasks with efficiency, precision, and safety.

Limitations of Workbenches

While workbenches offer numerous advantages, users may encounter certain limitations. Ergonomics can become a concern if the bench height or design does not accommodate the user’s posture, potentially leading to discomfort or repetitive strain injuries. Space constraints—such as a compact work area—can limit the size or placement of a workbench, affecting workflow and storage options. Inflexible or non-modular designs may restrict the workbench’s ability to adapt to evolving tasks or equipment needs.

Additionally, a lack of customization or accessory options may hinder the bench’s suitability for specialized work, and improper use or neglect of safety features can increase the risk of accidents or tool-related injuries.

Manufacturers are proactively addressing these challenges by introducing modular workbench systems that enable users to reconfigure layouts, add accessories, and scale storage to fit their needs. Ergonomic upgrades such as adjustable-height legs, anti-fatigue mats, and user-friendly edge profiles help prevent strain and promote comfort during extended use. Enhanced safety measures—like rounded corners, non-slip surfaces, and compliance with OSHA or ANSI standards—are becoming industry norms.

Are you trying to overcome a specific workbench limitation? Browse our troubleshooting guide and learn how to select customizable, ergonomic, and safe workbench solutions for your unique requirements.

Benefits of Workbenches

Work benches are foundational to productivity, efficiency, and safety in environments ranging from professional workshops to industrial manufacturing plants. Core benefits include:

- Organization and Workflow Optimization: Dedicated storage for tools, materials, and parts keeps everything accessible and reduces the time spent searching for equipment. This supports lean manufacturing and 5S principles, eliminating clutter and boosting efficiency.

- Enhanced Safety: Features such as non-slip surfaces, built-in guards, rounded edges, and ergonomic design minimize accident risk. Sturdy construction and controlled environments make it safer for users to operate hand and power tools.

- Versatility and Adaptability: Modern workbenches accommodate a wide variety of tasks—from electronics assembly and woodworking to laboratory experiments and metal fabrication. Customizable accessories and modular components ensure the bench evolves with your needs.

- Productivity Gains: A dedicated work area with integrated power, lighting, and storage enables users to focus on the task at hand, reducing setup and teardown times and facilitating uninterrupted workflows.

- Improved Ergonomics: Adjustable features allow users to work comfortably, reducing the risk of repetitive strain and supporting long-term health and well-being.

Whether for industrial, commercial, or hobbyist use, workbenches are indispensable tools that support efficiency, safety, and quality across countless applications.

Applications of Workbenches

Workbenches are utilized in a vast array of industries and activities, serving as the foundation for countless professional and creative tasks. Common applications include:

- Electronics: Assembly and repair of circuit boards, soldering, troubleshooting, and quality control testing.

- Woodworking and Carpentry: Precision cutting, planing, sanding, joinery, and finishing of wood projects.

- Automotive and Garage: Engine repairs, part replacements, diagnostic work, and vehicle modifications.

- Art and Craft: Painting, sculpting, jewelry making, model assembly, and other creative pursuits.

- Laboratory and Research: Sample analysis, chemical experimentation, and scientific instrumentation.

- Metalworking and Welding: Cutting, shaping, grinding, and assembling metal components.

- Textile and Sewing: Fabric cutting, measuring, sewing, tailoring, and pattern making.

- Gardening and Potting: Plant potting, seed starting, tool organization, and small-scale landscaping.

- Education and Training: Classroom workstations for hands-on STEM, shop, and vocational courses.

The versatility of workbenches makes them a cornerstone of productivity and organization, enabling professionals, students, and hobbyists to work efficiently and safely across a range of disciplines.

Are you looking for application-specific advice? Explore our detailed case studies and industry guides for more insight into choosing the right workbench for electronics, woodworking, automotive, or laboratory use.

Choosing an Appropriate Workbench

When selecting the best workbench for your needs, several key factors must be considered to ensure optimal fit and performance:

- Application Requirements: Define your primary tasks. Are you soldering electronics, assembling furniture, repairing cars, or conducting laboratory experiments?

- Size and Dimensions: Measure your workspace and consider the bench’s footprint, height, and work surface area to ensure it fits comfortably without hindering movement.

- Material and Durability: Choose materials—wood, steel, laminate, or specialized composites—that offer the durability, chemical resistance, and load capacity needed for your tasks.

- Storage and Organization: Determine your need for drawers, cabinets, bins, or overhead racks to organize tools and materials efficiently.

- Ergonomic Features: Adjustable height, anti-fatigue mats, and user-friendly designs enhance comfort and reduce strain during long work sessions.

- Integrated Accessories: Consider built-in lighting, power strips, vises, clamps, or ESD protection for efficiency and safety.

- Budget and Value: Balance your functional needs with your budget, factoring in long-term durability and potential for upgrades or modular expansion.

- Compliance and Safety: Ensure the workbench meets industry-specific safety standards, such as OSHA, ANSI, or ISO requirements.

Customer reviews, supplier comparisons, and expert recommendations can offer valuable insights when making your decision. Not sure where to start? Browse our workbench supplier directory or request a personalized quote.

Ask yourself: What are the must-have features for my workbench? Use our bench selection checklist to streamline your buying process and avoid common pitfalls.

Choosing the Right Workbench Supplier

For the best outcome when purchasing a workbench—whether for an industrial facility, educational laboratory, commercial shop, or home garage—compare multiple suppliers using our comprehensive directory. Each supplier’s profile page highlights their industry experience, product range, customization capabilities, and certifications. Use the integrated contact form to request quotes or ask specific questions.

Our patented website previewer helps you quickly assess each supplier’s specialization, such as custom fabrication, modular systems, or ESD-safe benches. For larger projects or to compare bulk pricing, use our RFQ (Request for Quote) tool to contact several suppliers simultaneously—saving time and ensuring you receive the most competitive offers.

Ready to find the perfect workbench manufacturer? Start your supplier search now and take the first step toward improving your workplace productivity, safety, and organization.

Still have questions about choosing, installing, or maintaining your new workbench? Contact our expert team or explore our knowledge base for detailed guides, installation tips, and maintenance best practices.

Check out our Hinges website

Check out our Plastic Bags website

What are the essential components of a workbench?

Essential components of a workbench include a durable work surface, sturdy frame and legs, integrated storage solutions like drawers and shelves, workholding accessories such as vises and clamps, as well as integrated lighting and power outlets. Some workbenches may feature specialized elements like ESD protection or fume extraction systems for specific applications.

What are the different types of workbenches available?

Common types of workbenches include electronics workbenches, woodworking workbenches, garage workbenches, and laboratory workbenches. Each type is designed with unique features tailored to its respective tasks, such as ESD-safety in electronics benches, heavy-duty vises for woodworking, rugged steel surfaces for garages, and chemical-resistant materials for laboratories.

What are some limitations of using workbenches?

Limitations of workbenches can include ergonomic concerns if the height or design is not ideal, limited space in compact areas, lack of adaptability in non-modular designs, and insufficient customization options. Neglecting safety features or failing to match the workbench to specific tasks can also pose risks.

What are the main benefits of using workbenches?

Workbenches offer improved organization, optimize workflow, enhance safety, support a variety of applications, and boost productivity. Features such as ergonomic design, adjustable height, integrated storage, and dedicated power sources help users work efficiently, safely, and comfortably.

In which industries and applications are workbenches commonly used?

Workbenches are used in electronics assembly, woodworking, automotive repair, art and craft, laboratory research, metalworking, textile and sewing, gardening, and education. Their versatility makes them a staple in professional, industrial, and hobbyist settings alike.

How should I choose the best workbench for my needs?

Consider your primary application, required size and dimensions, material durability, storage needs, ergonomic features, integrated accessories, budget, and safety standards. Review customer feedback, compare suppliers, and utilize selection checklists to ensure the chosen workbench meets your functional and budgetary requirements.

How can I find a reliable workbench supplier?

Use supplier directories to compare company experience, product selection, customization options, and certifications. Request quotes and evaluate offers using tools like RFQ (Request for Quote). Review supplier profiles and contact forms to match your project requirements with the most suitable manufacturer.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services