ESD cleanroom benches are purpose-built workstations that combine electrostatic discharge control with the stringent requirements of cleanroom environments. They are used wherever even trace contamination or a brief static event can jeopardize product quality, performance, or safety. Read More…

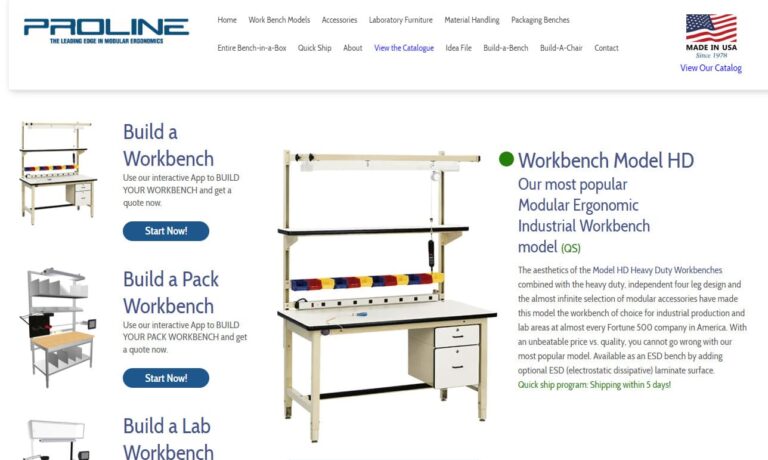

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

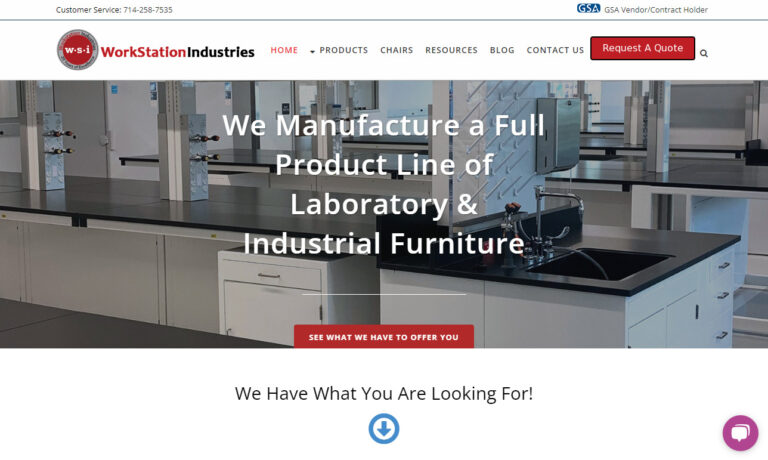

This progressive workstation manufacturer creates flexible, ergonomic solutions for a variety of work environments. ESD, clean room & lab benches, ball transfer assembly workstations, material handling flow rack stations, quick ship modular work benches & great accessories. With everything in-house, we ensure quality workmanship, great lead times & competitive prices for even custom bench designs.

Production Automation Corporation has been a distributor of products for general industrial manufacturing since 1973. We specialize in providing items used in electronic assembly and medical device manufacturing. As a manufacturer's representative, we have a large line of products such as anti fatigue mats, safety wear, chairs, cleaners, hand tools, microscopes, cabinets, workbenches and more.

Worksmart Systems designs ergonomic workstations providing customers with the necessary tools to reach six sigma lean manufacturing goals by eliminating waste, preventing defects and improving line efficiency. These are accomplished by our Fleximate® workstations such that our products can be joined together to create optimized assembly cells. We also offer floor and table top stations.

More ESD Cleanroom Bench Manufacturers

By pairing ESD-safe construction with cleanroom-approved materials and finishes, these benches support precision work in operations that demand tight control over particles, static electricity, and process flow.

At a functional level, ESD cleanroom benches are engineered to safeguard delicate electronic assemblies, micro-scale components, and precision devices from static-related damage while remaining compliant with cleanroom classifications ranging from ISO Class 3 through ISO Class 8. Grounded work surfaces, conductive or dissipative materials, and enclosed structural designs work together to create a workstation that satisfies both electrostatic discharge requirements and cleanroom protocols.

The Importance of ESD Control in Cleanrooms

Electrostatic discharge is a frequent but often unseen cause of failures in electronics manufacturing, semiconductor processing, medical device production, and aerospace assembly. Static charges can accumulate on operators, tools, or work surfaces and release suddenly into sensitive components. In cleanroom environments, this threat is intensified due to the use of extremely small parts, thin substrates, wafers, and dense circuitry.

ESD cleanroom benches address this challenge by providing a controlled means for static energy to flow safely to ground. Their work surfaces are manufactured to fall within defined resistance ranges that prevent sudden discharges while also limiting static buildup. Maintaining this balance is essential for protecting components without creating safety concerns for personnel or equipment.

Cleanroom Design and Contamination Prevention

In addition to static protection, cleanroom workstations must actively support contamination control. Conventional industrial benches may generate particles, retain debris, or release chemicals that interfere with cleanroom conditions. ESD cleanroom benches are designed with smooth, non-shedding materials and sealed connections to reduce particle generation and simplify cleaning.

Typical cleanroom-friendly features include stainless steel frames, low-outgassing powder-coated steel, solid laminate or phenolic resin work surfaces, and radiused edges that discourage particle accumulation. These design elements allow for routine wipe-downs and cleaning procedures using approved cleanroom disinfectants and solvents.

Common Applications and Industries

ESD cleanroom benches are widely used in electronics assembly and inspection, where printed circuit boards, microelectronics, and sensors require protection from static damage. Semiconductor manufacturing facilities depend on these benches for wafer handling, inspection, and packaging tasks that demand both ESD control and ultra-clean conditions.

Medical device production is another major use case, particularly for implantable devices, diagnostic electronics, and other regulated products that must meet strict cleanliness and quality standards. Aerospace and defense manufacturers also rely on ESD cleanroom benches to safeguard mission-critical components while maintaining consistent, traceable processes.

In research laboratories and pharmaceutical cleanrooms, these benches support sensitive instrumentation, sample handling, and controlled assembly work where static interference or contamination could compromise outcomes.

Materials and Structural Design

The effectiveness of an ESD cleanroom bench is closely tied to its materials and build quality. Work surfaces are commonly fabricated from static-dissipative laminates, conductive composites, or specialized ESD phenolic materials that deliver uniform electrical performance across the entire surface. These materials are designed to withstand repeated use and cleaning while maintaining stable resistance characteristics.

Frames and support systems are typically made from stainless steel or coated steel to resist corrosion, limit particle shedding, and accommodate grounding requirements. Hardware and joints are engineered to be flush and sealed, minimizing crevices where contaminants could collect.

Grounding plays a central role in overall performance. ESD cleanroom benches are designed to integrate with facility grounding networks and often include designated grounding points for wrist straps, mats, and tools. This ensures a continuous and dependable pathway for static dissipation throughout the workstation.

Ergonomics and Productivity

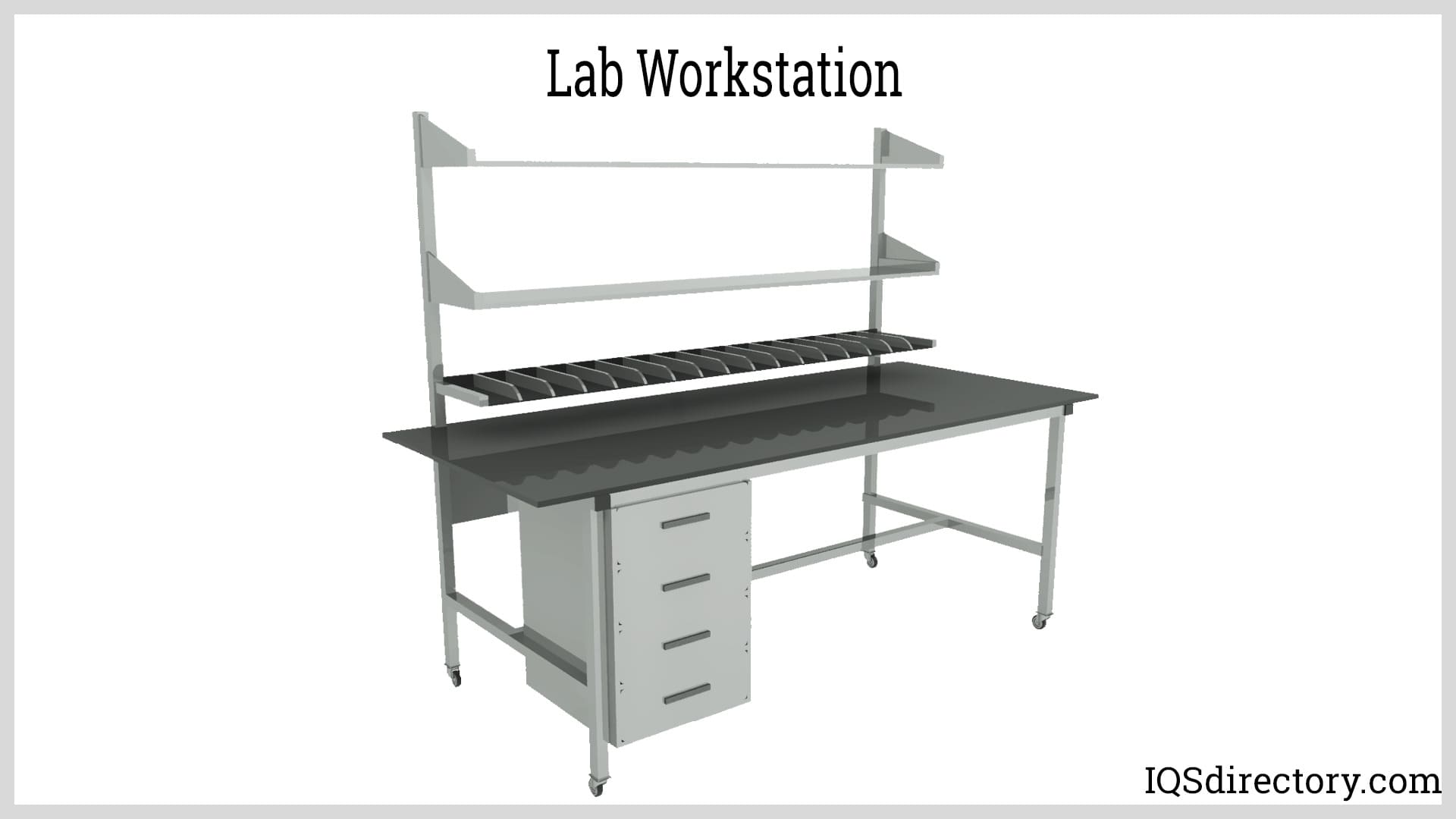

While cleanliness and static control are critical, operator comfort and efficiency are equally important considerations. Many ESD cleanroom benches feature adjustable heights, allowing users to work comfortably while seated or standing. Proper ergonomic design helps reduce fatigue, improve accuracy, and support extended production shifts without sacrificing quality.

Cleanroom-rated accessories such as shelving, task lighting, monitor arms, and integrated power solutions are often available to enhance organization and workflow. These components are designed to maintain airflow patterns and minimize particle disturbance while keeping tools and materials within easy reach.

Modularity and Custom Configuration

Workflows and cleanroom layouts can vary significantly between facilities, making flexibility an important advantage. Modular ESD cleanroom bench systems allow users to configure workstations with drawers, instrument shelves, lighting, and enclosure panels while preserving ESD performance and cleanroom compatibility.

Customization options may include specific dimensions, higher load capacities, or integration with laminar flow hoods and enclosures. This adaptability enables organizations to create workstations tailored to their processes without compromising compliance or performance.

Key Considerations for Buyers

When selecting ESD cleanroom benches, buyers typically evaluate several critical factors. Compatibility with the required cleanroom classification is essential, as materials and construction must meet specific ISO standards. The electrical properties of the work surface should align with established ESD guidelines to ensure dependable static control.

Long-term durability is another major concern, particularly in high-volume production settings. Buyers often seek benches that retain consistent ESD performance despite frequent cleaning, heavy use, and exposure to approved chemicals. Ease of maintenance, corrosion resistance, and structural integrity all influence total cost of ownership.

Scalability also plays a role in purchasing decisions. Facilities planning for expansion or process changes often favor modular systems that can be reconfigured or expanded over time, protecting their initial investment.

Advantages of High-Quality ESD Cleanroom Benches

Investing in well-designed ESD cleanroom benches directly supports higher product quality, improved yields, and smoother operations. By minimizing the risk of electrostatic damage, these benches help reduce scrap, rework, and costly component failures. Their cleanroom-compatible construction also supports regulatory compliance and audit preparedness in controlled environments.

Thoughtful design improves organization and operator comfort, leading to better productivity and fewer errors. Over time, these benefits contribute to greater consistency, reliability, and overall manufacturing efficiency.

Addressing Diverse Buyer Needs

Whether engineers are researching static control solutions or procurement teams are comparing workstation specifications, ESD cleanroom benches serve a wide range of buyer intent. They bring together ESD protection, contamination control, ergonomic design, and modular flexibility, making them a core element of modern cleanroom operations.

By understanding how application requirements, materials, and design features intersect, organizations can choose ESD cleanroom benches that meet current standards while remaining adaptable for future needs. In environments where precision, cleanliness, and reliability are critical, these benches play a vital role in protecting both products and processes.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services